From runabouts and tinnies to newly fabricated builds, our boat spray-painting services deliver a fresh, long-lasting finish designed specifically for aluminium vessels. We specialise in surface restoration, corrosion treatment, colour changes, and applying premium marine-grade coatings that bond correctly to aluminium.

Whether you’re refreshing faded paint, repairing wear, or coating a brand-new fabrication, we use durable coatings that resist UV, salt, water, and harsh marine conditions—keeping your boat looking sharp in and out of the water.

Explore a selection of our completed works in our gallery, showcasing exceptional transformations and flawless resprays, delivered with our unwavering commitment to premium craftsmanship and lasting quality.

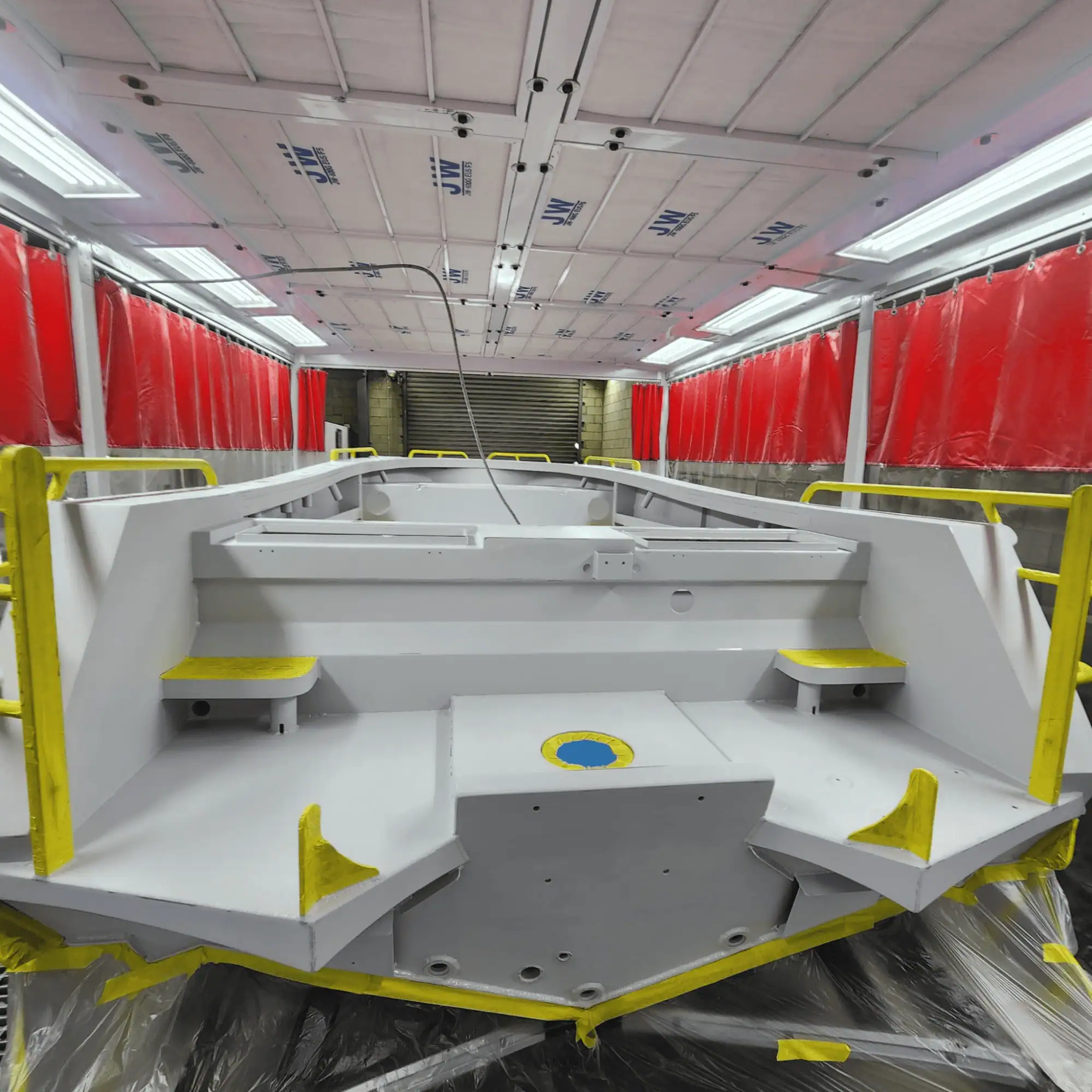

Premium Aluminium Hull Fairing & Refinishing

All aluminium surfaces were thoroughly sanded and prepared for refinishing inside & out.

Extensive surface levelling was carried out to remove visible ripples, involving approximately 150 labour hours across both sides of the hull, the top gunnel, and selected areas of the transom to achieve a smooth, ripple-free finish.

Multiple epoxy applications were carried out, with five epoxy coats applied to build surface integrity and ensure a high standard of straightness prior to topcoat application

Apply multiple base colours inside & outside for 10 hours in one hit for long last finish

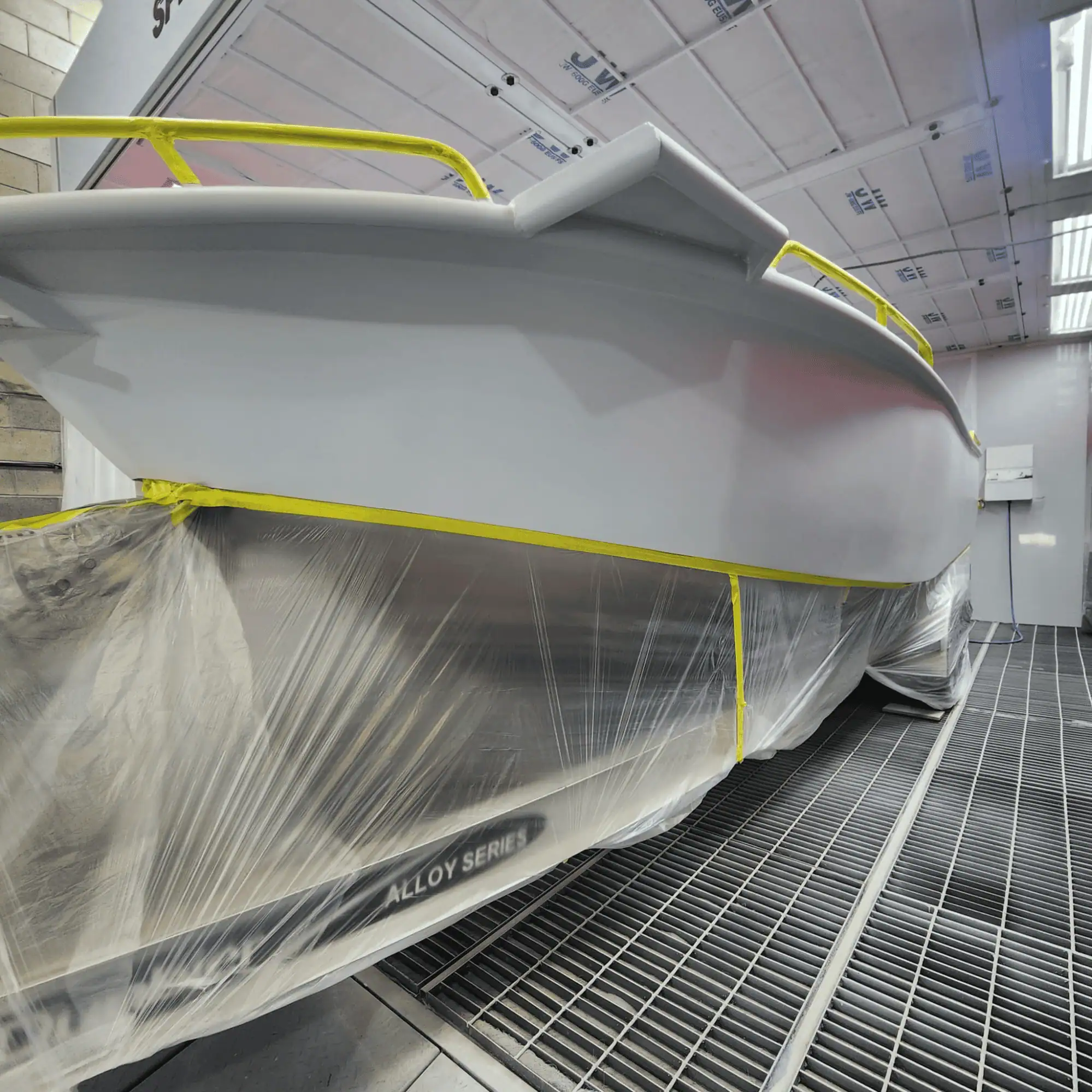

Premium Aluminium Hull Fairing & Refinishing

All aluminium surfaces were thoroughly sanded and prepared for refinishing inside & out.

Extensive surface levelling was carried out to remove visible ripples, involving approximately 150 labour hours across both sides of the hull, the top gunnel, and selected areas of the transom to achieve a smooth, ripple-free finish.

Multiple epoxy applications were carried out, with five epoxy coats applied to build surface integrity and ensure a high standard of straightness prior to topcoat application

Apply multiple base colours inside & outside for 10 hours in one hit for long last finish

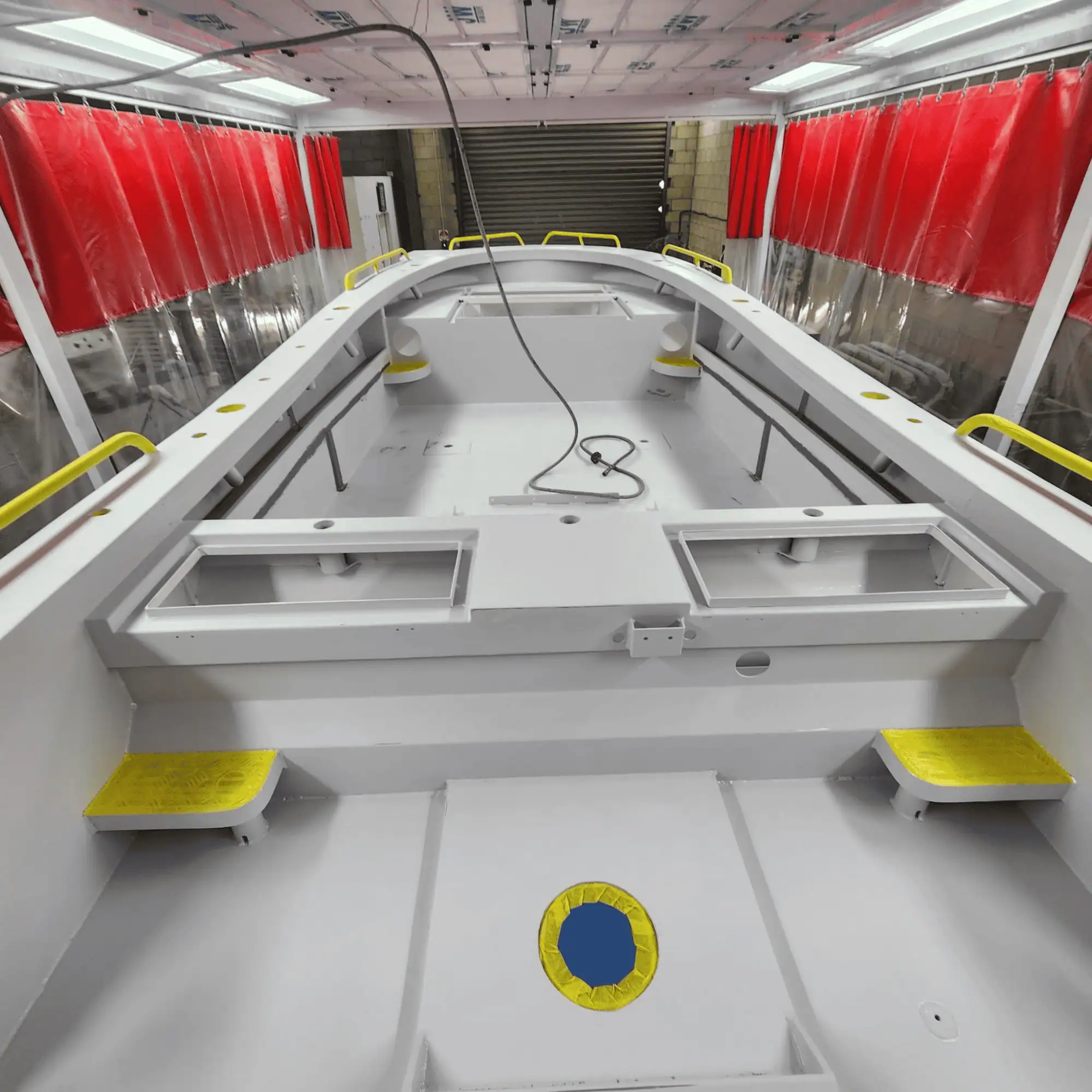

Post-Fabrication Gunnel Refinishing

Thorough sanding was carried out in the fabricated gunnel areas and partially along the hull sides to prepare the surface for refinishing.

Localised surface imperfections were rectified prior to epoxy application.

Epoxy and primer systems were applied to build a smooth, stable foundation for topcoat application.

The vessel was masked multiple times to protect surrounding and unpainted areas throughout the coating process.

Multiple base colour layers and topcoats were applied to achieve a durable, long-lasting finish in line with Stabicraft premium standards.

Post-Fabrication Gunnel Refinishing

Thorough sanding was carried out in the fabricated gunnel areas and partially along the hull sides to prepare the surface for refinishing.

Localised surface imperfections were rectified prior to epoxy application.

Epoxy and primer systems were applied to build a smooth, stable foundation for topcoat application.

The vessel was masked multiple times to protect surrounding and unpainted areas throughout the coating process.

Multiple base colour layers and topcoats were applied to achieve a durable, long-lasting finish in line with Stabicraft premium standards.

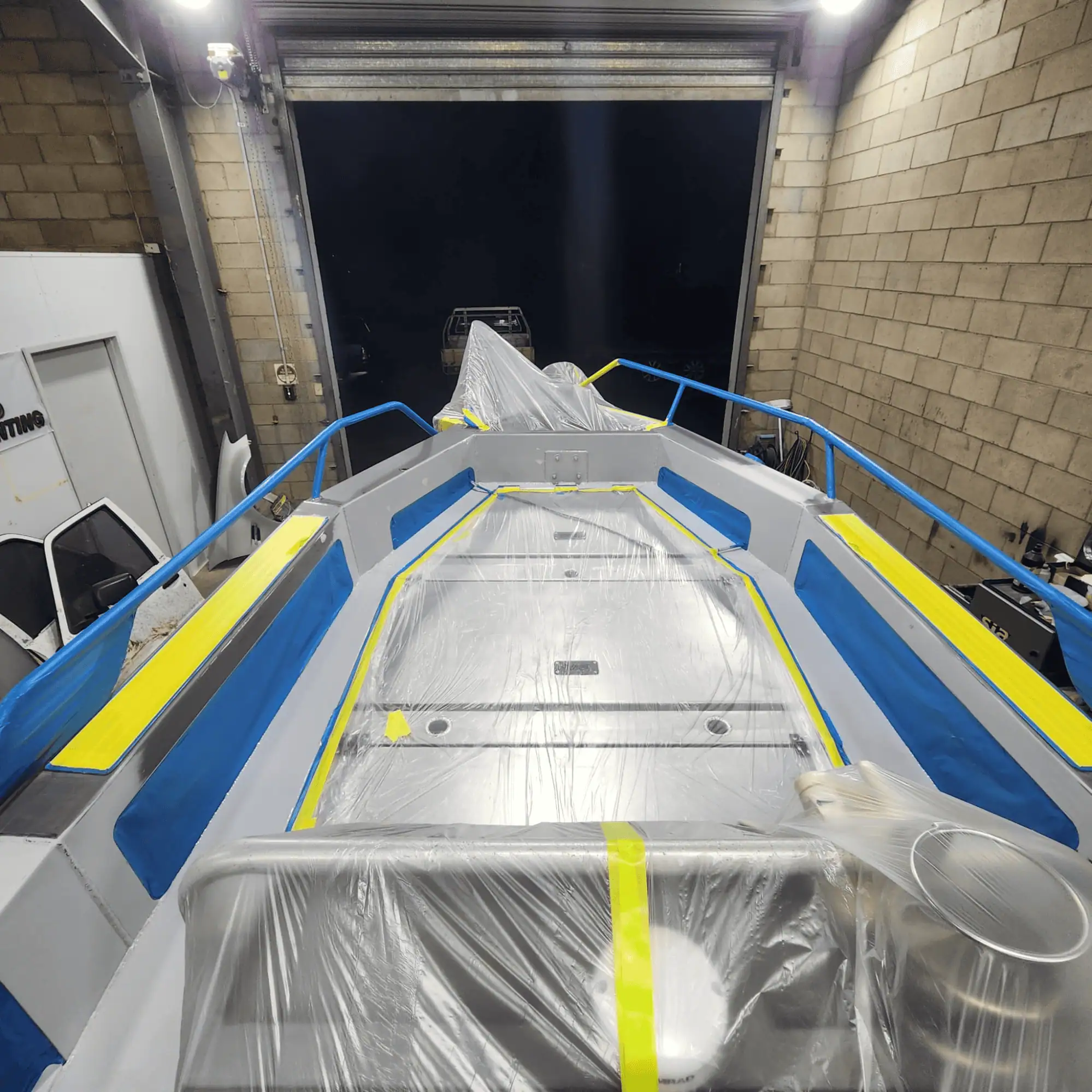

Spraypainting the inside & outside of the trailer boat

Initial surface sanding had been carried out by the owner; however, all relevant areas were re-sanded thoroughly to meet our preparation standards.

Any remaining pinholes, voids, or surface imperfections were rectified prior to epoxy application.

A primer system was applied to establish a smooth, stable foundation for subsequent coatings.

Masking was carried out throughout the process to protect all areas not designated for painting.

Multiple base coats and topcoats were applied to achieve a durable, long-lasting marine finish.

Spraypainting the inside & outside of the trailer boat

Initial surface sanding had been carried out by the owner; however, all relevant areas were re-sanded thoroughly to meet our preparation standards.

Any remaining pinholes, voids, or surface imperfections were rectified prior to epoxy application.

A primer system was applied to establish a smooth, stable foundation for subsequent coatings.

Masking was carried out throughout the process to protect all areas not designated for painting.

Multiple base coats and topcoats were applied to achieve a durable, long-lasting marine finish.

With over 30 years of spray-painting experience, we deliver premium automotive and marine work, helping our customers and businesses keep their vehicles looking great